47 min read

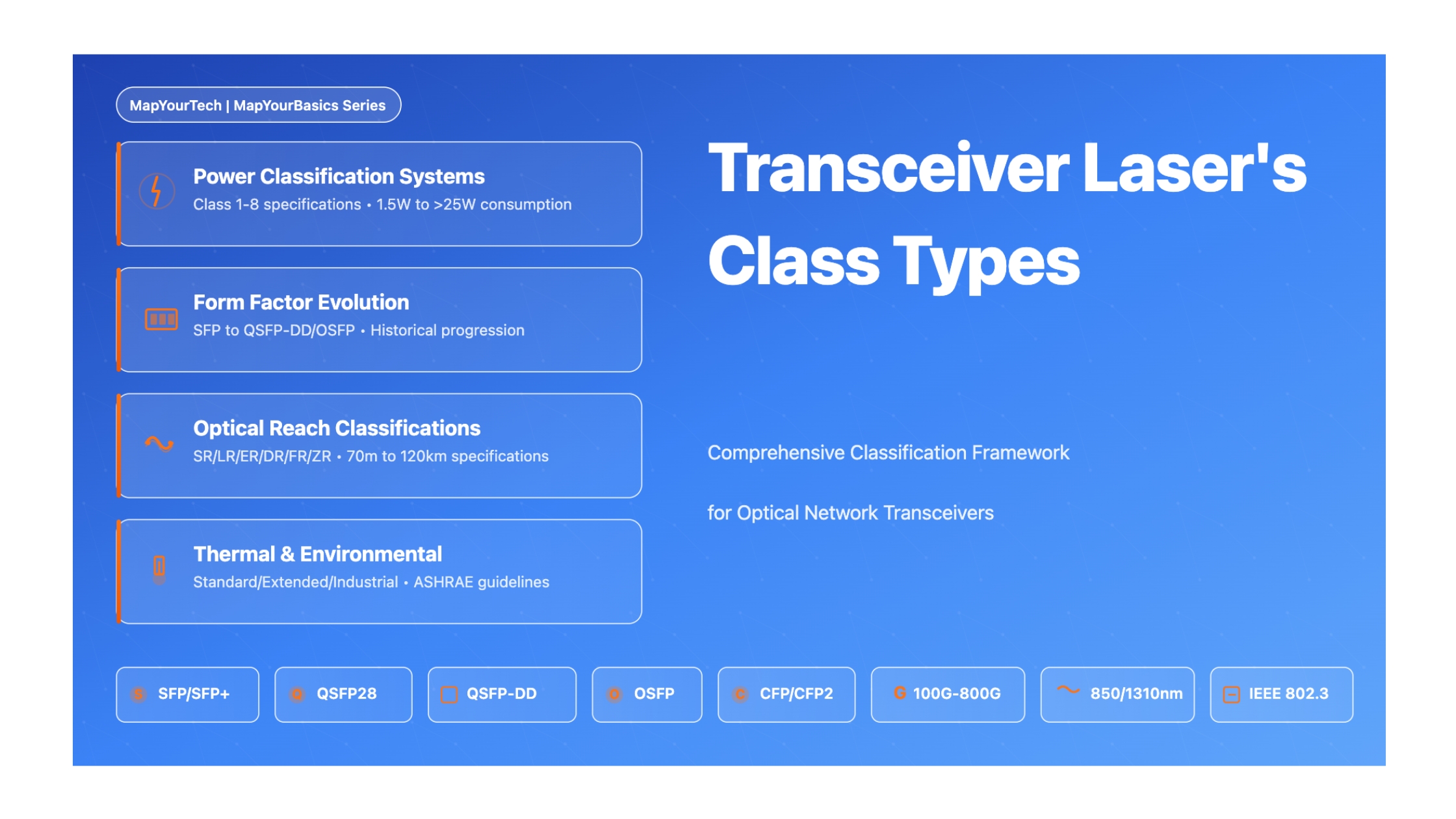

Transceiver Laser Safety Classes & Classifications

A Comprehensive Guide to Understanding Laser Safety Standards, Power Limits, Hazard Levels, and Regulatory Compliance in Optical Transceivers and Telecommunications Systems

Introduction

Laser safety in optical transceivers represents a critical aspect of telecommunications infrastructure that directly impacts the protection of technicians, network engineers, end-users, and equipment during installation, operation, and maintenance activities. Modern optical communication systems utilize lasers operating across various wavelengths and power levels, ranging from low-power short-reach transceivers deployed in data centers to high-power coherent transmission systems spanning thousands of kilometers in long-haul networks. Understanding laser safety classifications is absolutely essential for network engineers, data center operators, fiber optic technicians, telecommunications professionals, and anyone working with fiber optic equipment in any capacity.

The classification system for laser safety has evolved significantly since the early days of optical communications in the 1970s. Today's comprehensive standards, primarily governed by the International Electrotechnical Commission standard IEC 60825-1 and the U.S. Food and Drug Administration regulations 21 CFR 1040.10 and 1040.11, provide a detailed framework for categorizing lasers based on their potential to cause biological harm to the human eye and skin. These classifications range from Class 1 lasers that are considered inherently safe under all conditions of normal use, through intermediate classes with increasing hazard levels, all the way to Class 4 lasers that represent severe hazards requiring extensive safety controls and protective measures.

Optical transceivers deployed in telecommunications networks typically fall into Class 1 or Class 1M categories under normal operating conditions, meaning they are considered safe without requiring special precautions during routine use. However, it's important to understand that higher-power coherent transceivers used in long-haul metropolitan and intercontinental applications may incorporate embedded lasers that would individually be classified as Class 3R, Class 3B, or even Class 4 if accessed directly without protective enclosures. The fundamental engineering principle applied throughout the industry is that the overall transceiver product must be classified and certified as Class 1, even if it contains embedded lasers of significantly higher classifications, through the implementation of proper engineering controls including mechanical interlocks, automatic power reduction systems, electromagnetic shutters, and robust protective enclosures that prevent human access to hazardous radiation levels.

Real-World Relevance and Critical Importance

Understanding laser safety classifications carries profound importance for multiple critical reasons. First and foremost, it ensures full compliance with international and national regulations, helping organizations avoid legal issues, regulatory penalties, and potential litigation. Second, it provides essential protection for personnel from serious eye and skin injuries that can result from direct beam exposure, specular reflections from shiny surfaces, or even diffuse reflections from certain high-power systems. Third, it enables proper selection and specification of appropriate personal protective equipment such as wavelength-specific laser safety eyewear with adequate optical density ratings. Fourth, it informs the development of correct handling procedures during installation, maintenance, and troubleshooting activities. Finally, it helps organizations develop comprehensive and appropriate safety training programs for technical staff at all levels from entry-level technicians to senior network engineers.

The critical importance of laser safety extends far beyond mere regulatory compliance checkboxes. In practical terms, even very brief exposure to certain laser classes can cause permanent and irreversible eye damage, including retinal burns that may not manifest immediately but result in permanent vision loss. The human eye is particularly vulnerable to laser radiation at wavelengths in the visible spectrum (400-700 nm) and near-infrared spectrum (700-1400 nm), where the eye's natural optical system acts as a powerful focusing mechanism, concentrating incoming laser light onto an extremely small spot on the delicate retinal tissue. Many optical transceivers operate precisely within this most hazardous range, commonly using wavelengths such as 850 nm for short-reach multimode applications, 1310 nm for intermediate-reach single-mode systems, and 1550 nm for long-haul transmission where fiber attenuation is minimized. Understanding the specific risks associated with these wavelengths and the protective measures required for each laser classification is absolutely essential for maintaining a safe working environment for all personnel who may come into contact with optical networking equipment.

Laser Safety Classes - Complete Classification System

The laser safety classification system divides all laser products into distinct categories based on their measured potential to cause biological harm under specified exposure conditions. This comprehensive section provides detailed coverage of each safety class, including precise power limits, specific hazard characteristics, typical applications in telecommunications, required safety controls, and regulatory labeling requirements.

Class 1: Inherently Safe Laser Products

Class 1 represents the safest category of all laser products. Lasers and laser products in this classification are considered completely incapable of producing hazardous levels of optical radiation under any reasonable condition of normal use, including prolonged direct viewing with the naked eye. The accessible emission from a Class 1 laser product must not exceed the carefully calculated Class 1 Accessible Emission Limit (AEL), which is conservatively set at levels significantly below the Maximum Permissible Exposure (MPE) for both eye and skin exposure even under worst-case exposure scenarios including continuous viewing for extended periods.

Class 1 Technical Specifications and Characteristics

Power Limits: For continuous wave visible lasers operating in the 400-700 nm wavelength range, the accessible emission limit is approximately 0.39 mW when integrated over the standard 7 mm limiting aperture that represents a fully dilated human pupil. For infrared wavelengths around 1550 nm commonly used in telecommunications applications, the Class 1 limit is approximately 10 mW measured under standardized conditions with specific measurement apertures and acceptance angles as defined in IEC 60825-1.

Hazard Assessment: No biological hazard exists under any reasonably foreseeable condition of use including accidental viewing, prolonged intentional viewing, or viewing with moderate optical magnification.

Required Safety Controls: No specific control measures are required beyond the protective housing that defines the product boundary. No laser hazard warning labels are required on Class 1 products, though manufacturers often include informational labels about embedded lasers.

Typical Applications in Telecommunications: The vast majority of optical transceivers including SFP, SFP+, QSFP, QSFP28, QSFP-DD, and OSFP modules; enclosed DWDM terminals and reconfigurable optical add-drop multiplexers (ROADMs); optical amplifiers with proper protective enclosures; all standard fiber optic networking equipment used in data centers, enterprise networks, and service provider facilities; optical time-domain reflectometers (OTDRs) with proper beam confinement; and fiber optic test equipment designed for field deployment.

Critical Safety Information for Service Personnel

While Class 1 laser products are completely safe during normal operation and use, it is absolutely critical to understand that they may contain embedded lasers of significantly higher classifications (Class 3R, 3B, or even 4) that become accessible during service, maintenance, or repair activities when protective housings are removed or interlocks are defeated. Service labels must prominently warn qualified technicians about these internal hazards with language such as "CAUTION - INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED. AVOID DIRECT EXPOSURE TO BEAM." Only personnel who have received appropriate laser safety training and understand the specific hazards should perform service activities that may expose them to embedded laser sources. Many high-end optical transceivers and DWDM equipment carry detailed service manuals specifying required safety procedures and personal protective equipment for authorized service personnel.

Class 1M: Safe for Naked Eye Viewing but Hazardous with Optical Instruments

Class 1M was introduced in the comprehensive 2001 revision of IEC 60825-1 to address a specific and important safety scenario that was not adequately covered by previous classification schemes. The "M" designation stands for "magnifying optical instruments" or "magnified viewing," indicating the specific nature of the hazard. Class 1M lasers are completely safe when viewed with the naked eye under all normal circumstances, but they may become hazardous when viewed through certain optical instruments such as binoculars, telescopes, microscopes, or fiber optic inspection scopes that can collect and concentrate the laser beam onto a smaller area of the retina than the natural pupil diameter would allow.

This classification typically applies to laser sources with either very large beam diameters significantly exceeding the 7 mm human pupil diameter, or lasers with high divergence angles that cause the beam to spread out rapidly with distance. While the irradiance measured through a 7 mm aperture representing the naked eye remains below hazardous levels, optical instruments with larger collection apertures (standardized as 50 mm in the classification testing procedures) can gather substantially more optical power and focus it onto the retina, potentially exceeding safe exposure levels. Class 1M is particularly relevant for fiber optic communication systems where optical fibers, when disconnected from equipment, may emit a highly diverging cone of light that appears safe to the naked eye but can become concentrated and hazardous when viewed through common fiber inspection microscopes used by technicians during connector cleaning and inspection procedures.

Class 1M Technical Specifications and Characteristics

Power Limits: The accessible emission must exceed the Class 1 limits when measured through the standard 50 mm aperture used to simulate optical instrument collection, but must remain below Class 1 limits when measured through the 7 mm aperture representing naked eye viewing. For infrared wavelengths around 1550 nm with high divergence, the typical power limit is approximately 40 mW measured through a 50 mm aperture at specified measurement distances with defined divergence criteria and acceptance angles.

Hazard Assessment: Completely safe for brief or extended naked-eye viewing under all normal conditions. Potentially hazardous when viewed through collecting optical instruments including but not limited to binoculars, telescopes, magnifying glasses, fiber inspection microscopes, and camera lenses, particularly those with large entrance pupils.

Required Safety Controls: Specific warning labels are required indicating the particular hazard associated with viewing through optical instruments. The standard warning states "CAUTION - LASER RADIATION. DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS." No other specific control measures are required for normal naked-eye operation, but organizations should implement procedures and training to prevent use of optical instruments for direct viewing of potential Class 1M sources.

Typical Applications in Telecommunications: Fiber optic transmitters and transceivers with highly divergent output beams particularly those using multimode fiber with large numerical aperture; many short-reach optical transceivers operating at 850 nm wavelength when fiber connectors are unplugged during service; VCSEL-based transceivers with inherently divergent emission characteristics; some optical power meters and test equipment with divergent indicator beams; alignment lasers equipped with beam expansion optics for construction and installation applications.

Technicians and field engineers working with optical networking equipment must be specifically trained to understand that fiber inspection microscopes, which are essential tools for verifying connector cleanliness and identifying physical damage, can transform what appears to be a safe Class 1M emission into a potentially hazardous exposure if used to view an active laser output. Standard operating procedures should mandate that all fiber connections be verified as unpowered or that transceivers implement automatic power reduction before any fiber inspection or cleaning activities are performed. Power meters should be used to confirm zero optical power before applying inspection equipment to fiber end-faces, particularly in DWDM systems where multiple wavelengths may be present.

Class 1C: Contact Application Laser Products

Class 1C represents the most recent addition to the laser safety classification system, introduced in the 2014 edition of IEC 60825-1 (Edition 3.0). This specialized classification was created to address laser products that are designed for deliberate contact application directly to the skin or other tissue surfaces. The "C" designation stands for "contact," reflecting the intended mode of use where the laser applicator is placed directly against the target tissue during operation. Class 1C products include cosmetic laser devices for hair removal and skin rejuvenation, low-level laser therapy devices for pain management and wound healing, and certain therapeutic medical lasers for dermatological treatments.

The fundamental principle underlying Class 1C classification is that these products are considered safe when used as specifically intended—with the laser delivery system in direct contact with the target tissue—but may present hazards if the beam becomes accessible for ocular viewing when the device is operated without the intended contact condition. This classification acknowledges that certain medical and cosmetic applications require power levels that would normally be classified as Class 3R or higher, but the contact application mode inherently limits exposure to the small area of tissue being treated rather than allowing beam propagation that could reach the eyes.

Class 1C Technical Specifications and Characteristics

Power Limits: Power limits vary significantly based on the specific application area and applicable vertical standards (such as IEC 60601-2-22 for medical laser equipment). Generally, Class 1C products may exceed Class 1 power limits by significant margins because exposure is limited to the contact application area rather than potential ocular exposure. Specific limits are defined by the combination of general laser safety standards and application-specific vertical standards.

Hazard Assessment: Considered safe when used in the intended contact mode with proper application technique. May present eye or skin hazards if operated without maintaining intended contact, if beam becomes accessible during improper use, or if device is modified or malfunctions. Assessment must consider both the intended use scenario and reasonably foreseeable misuse conditions.

Required Safety Controls: Products must incorporate design features ensuring that laser emission occurs only during proper contact application. Contact sensors must detect presence of tissue and prevent or terminate emission if contact is lost. Interlocks must prevent emission if applicator tip is removed or damaged. Comprehensive user instructions must clearly describe proper application technique and warnings against misuse. Products must comply with applicable vertical standards specific to their application area in addition to general laser safety requirements.

Applications in Healthcare and Cosmetics: Home-use and professional cosmetic laser devices for hair removal, tattoo removal, and skin resurfacing; low-level laser therapy (LLLT) devices for pain management, inflammation reduction, and tissue healing; photobiomodulation devices for wound care and post-surgical recovery; dermatological treatment devices for acne, pigmentation, and vascular lesions; dental laser devices for certain soft tissue procedures. Class 1C has very limited application in telecommunications and optical networking, though some specialized fiber optic test equipment or fusion splicers might theoretically fall into this category if designed for contact operation.

Regulatory Complexity and Compliance Requirements

Class 1C laser products face particularly complex regulatory requirements because they typically fall under multiple regulatory frameworks simultaneously. In addition to laser safety regulations (IEC 60825-1 and national equivalents), these products must comply with medical device regulations if used for therapeutic purposes, cosmetic device regulations if used for aesthetic applications, and consumer product safety regulations if sold for home use. In the United States, Class 1C medical laser devices must comply with both FDA laser product performance standards (21 CFR 1040.10/11) and medical device requirements. In the European Union, they must meet both laser safety standards (EN 60825-1) and medical device regulations (MDR 2017/745) or general product safety requirements depending on intended use.

Manufacturers of Class 1C products must demonstrate that their contact detection mechanisms are reliable and failsafe, meaning they default to preventing emission rather than allowing it when sensors malfunction or power is interrupted. Clinical testing may be required to establish safety and efficacy for medical claims. User instructions must be exceptionally clear, often requiring pictorial guides and explicit warnings against attempting to modify the device or defeat safety features. The multi-regulatory framework creates significant compliance burden but ensures that these products, which consumers may use at home without professional supervision, maintain adequate safety standards.

Class 2: Low-Power Visible Laser Products with Aversion Response Protection

Class 2 represents a unique laser classification that applies exclusively to visible wavelength lasers (400-700 nm spectral range) emitting at power levels low enough that the human aversion response provides adequate protection against retinal injury. The aversion response is a natural protective mechanism consisting of the blink reflex, pupil constriction, and the instinctive tendency to look away from bright light sources. These combined responses typically occur within 0.25 seconds of exposure to bright visible light. Class 2 classification is based on the principle that for visible lasers at sufficiently low power levels, this natural aversion response will limit exposure duration such that the eye's maximum permissible exposure is not exceeded even for direct beam viewing.

The 0.25 second exposure duration is a critical parameter in Class 2 classification. At power levels below approximately 1 milliwatt (1 mW), the radiant exposure to the retina during this brief aversion response period remains below the threshold for thermal damage. However, deliberate staring into a Class 2 laser beam for extended periods (defeating the natural aversion response) can result in retinal injury. This creates an interesting safety paradigm where brief accidental exposure is considered safe, but prolonged intentional viewing is not. Class 2 lasers are commonly encountered in everyday life including supermarket barcode scanners, laser pointers sold for presentation purposes, laser-based alignment tools used in construction, and visible indicator beams in surveying equipment.

Class 2 Technical Specifications and Characteristics

Power Limits: Maximum accessible emission of 1 milliwatt (1 mW) for continuous wave visible lasers operating in the 400-700 nm wavelength range. For pulsed visible lasers, limits are based on radiant exposure per pulse and total energy, calculated to ensure that exposure during the 0.25 second aversion response period does not exceed maximum permissible exposure values. The 1 mW limit assumes collimated or slightly divergent beams; highly divergent visible beams may qualify as Class 2M instead.

Hazard Assessment: Low risk for brief accidental exposure due to natural aversion response providing protection. Considered a chronic viewing hazard if someone deliberately stares into the beam for extended periods (several seconds or longer), defeating the protective aversion response. Risk increases if viewed at close range where irradiance is higher. Not considered a fire hazard or skin hazard at these power levels.

Required Safety Controls: Warning label required stating "CAUTION - LASER RADIATION. DO NOT STARE INTO BEAM." Some jurisdictions require additional warnings about not pointing lasers at people or animals. No engineering controls required beyond basic product housing. Administrative controls should include user training about not deliberately staring at beam and not pointing lasers at eyes of people or animals. Organizations using Class 2 lasers should implement policies prohibiting misuse.

Applications in Various Industries: Retail barcode scanners at checkout counters (typically Class 2, though some may be Class 1 if properly enclosed); laser pointers for presentations, astronomy, and education (often regulated due to misuse potential); construction and carpentry alignment lasers for leveling and line projection; surveying equipment with visible aiming beams; laboratory demonstration lasers for physics and optics education; visible fault locators (VFLs) used in fiber optic installations for tracing fiber runs and identifying breaks. Note that Class 2 has limited direct application in telecommunications data transmission since most optical systems use invisible infrared wavelengths (850nm, 1310nm, 1550nm), but visible alignment and test tools are ubiquitous in fiber optic installations.

Special Considerations and Misuse Prevention

Class 2 laser pointers have been subject to increasing regulatory scrutiny due to widespread misuse incidents including pointing at aircraft, aiming at law enforcement officers, and irresponsible use at public events. While the 1 mW power limit means brief exposure is unlikely to cause permanent injury, such misuse creates serious safety hazards including temporary flash blindness, distraction of pilots or drivers, and potential injury if the targeted person attempts to avoid the laser and falls or crashes. Many jurisdictions have enacted specific regulations prohibiting laser pointing at aircraft, vehicles, or people, with substantial penalties for violations.

Additionally, the market has seen proliferation of devices labeled as "Class 2" or "safe laser pointers" that actually exceed Class 2 power limits, sometimes dramatically. Consumers should purchase laser pointers only from reputable sources, verify that products carry proper FDA certification labels (in the US) or CE markings (in EU), and never attempt to modify laser pointers to increase output power. Parents and educators should supervise children's use of laser pointers and emphasize that these are not toys. Professional users should implement administrative controls including training on appropriate use, policies against pointing lasers at people, and disciplinary measures for misuse.

The aversion response protection concept in Class 2 creates an important limitation: this protective mechanism only functions for visible wavelengths where the brightness of the light triggers the response. Infrared lasers at similar power levels (such as 1 mW at 1310 nm or 1550 nm) are invisible to the human eye and therefore do not trigger any aversion response, necessitating different classification (typically Class 3R for infrared at these power levels). This wavelength dependency is a critical distinction that must be understood by anyone specifying or using laser equipment.

Class 2M: Low-Power Visible Lasers with Magnified Viewing Hazard

Class 2M represents the visible-light analog to Class 1M, combining the aversion response concept of Class 2 with the magnified viewing hazard of the M classification. These are visible wavelength lasers (400-700 nm) that emit at power levels where the natural aversion response provides protection for brief naked-eye viewing, similar to Class 2, but viewing through optical instruments that collect and concentrate the beam may create hazardous exposure conditions even during the brief aversion response period. The dual-aspect safety profile of Class 2M lasers requires careful consideration of both exposure duration and viewing conditions.

Class 2M typically applies to visible lasers with large beam diameters or high divergence, where the power measured through a 7 mm aperture (representing the naked eye) remains within Class 2 limits, but the power measured through a 50 mm aperture (representing optical instruments) exceeds Class 2 limits. The visible nature of the emission provides some natural protection through the aversion response, but this protection may be insufficient if the viewer is using binoculars, telescopes, or other collecting optics that gather more optical power than the natural pupil can collect. Examples include visible laser projection systems with beam expansion, visible alignment lasers with diverging beams used in large-scale construction projects, and specialized visible laser sources used in metrology and inspection applications where large-area illumination is required.

Class 2M Technical Specifications and Characteristics

Power Limits: Accessible emission must exceed Class 2 limits (1 mW) when measured through a 50 mm aperture but remain below Class 2 limits when measured through a 7 mm aperture for the 0.25 second aversion response duration. Typical power range is approximately 1-4 mW through the 50 mm aperture for highly divergent visible beams. Specific limits depend on beam divergence angle, wavelength within the visible spectrum, and whether the laser is continuous wave or pulsed.

Hazard Assessment: Safe for brief naked-eye viewing (≤0.25 seconds) due to aversion response protection, assuming the viewer is not using optical instruments. Potentially hazardous for extended naked-eye viewing if aversion response is deliberately overcome. Potentially hazardous even for brief viewing when using optical instruments including binoculars, telescopes, camera lenses with telephoto capability, or any collecting optics with entrance pupils larger than the natural pupil diameter. Not considered a fire or skin hazard.

Required Safety Controls: Dual-warning labels required addressing both hazards: "CAUTION - LASER RADIATION. DO NOT STARE INTO BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS." Users must be trained about both aspects of the hazard: avoiding deliberate staring (even though beam is visible) and absolutely avoiding viewing through any optical instruments. Administrative controls should prohibit use of optical instruments for direct beam viewing. Organizations deploying Class 2M lasers should consider access controls if the lasers are used in areas where public might attempt to view with personal optical instruments (such as public astronomical observation sites).

Applications Across Industries: Visible laser projectors with beam expansion for large-venue entertainment or advertising; visible alignment lasers for large-scale construction, civil engineering, or architectural surveying applications; laser-based leveling systems with expanded visible reference lines for industrial alignment; specialized measurement and inspection systems using expanded visible laser illumination; educational demonstration equipment showing expanded visible laser beams; meteorological equipment (LIDAR systems) using visible wavelengths with deliberate beam expansion for atmosphere scanning. Class 2M has minimal application in standard telecommunications data transmission but may appear in specialized visible-wavelength free-space optical communication systems or experimental visible-light communication (VLC) research setups.

Organizations using Class 2M lasers face a training challenge: users must understand that despite the laser being visible (and therefore "obviously there"), it still presents hazards that may not be intuitively obvious. The dual nature of the hazard—both extended viewing without optics AND brief viewing with optics—requires comprehensive training that goes beyond the simple "don't stare at lasers" message appropriate for Class 2. Procedures must explicitly prohibit use of optical viewing aids including cameras with telephoto lenses, which users might not immediately recognize as hazardous when pointed toward a Class 2M source. Signage should clearly indicate both aspects of the hazard to protect both workers and visitors.

Class 3R: Low-Risk Lasers with Restricted Direct Viewing

Class 3R represents a significant step up in hazard level compared to Classes 1, 1M, 2, and 2M. The "R" designation stands for "restricted" or "reduced requirements" compared to the higher Class 3B, but Class 3R lasers are nonetheless capable of causing eye damage through direct beam viewing, and the risk is considered substantial enough to warrant careful handling procedures and safety controls. Class 3R was introduced in the 2001 revision of IEC 60825-1 to bridge the gap between low-hazard and high-hazard classifications, providing a classification for lasers that pose some risk but don't require the extensive controls mandated for Class 3B.

The accessible emission limit for Class 3R is set at five times (5×) the Accessible Emission Limit for Class 1 (for invisible wavelengths) or Class 2 (for visible wavelengths). For continuous wave visible lasers, this means Class 3R encompasses the power range from 1 mW to 5 mW. For invisible infrared wavelengths commonly used in telecommunications (such as 1310 nm and 1550 nm), the Class 3R range is approximately 2 mW to 50 mW, depending on specific beam characteristics and measurement conditions. While direct beam viewing can cause retinal damage, particularly with prolonged exposure or at close range, the risk is considered lower than Class 3B because the power levels are not sufficient to cause instant injury and diffuse reflections from matte surfaces are generally not hazardous.

Class 3R Technical Specifications and Characteristics

Power Limits: For visible CW lasers (400-700 nm): 1 mW to 5 mW. For near-infrared around 1550 nm: approximately 2-50 mW depending on beam divergence and exposure conditions. Generally defined as up to 5× the AEL for Class 1 or Class 2. For pulsed lasers, limits are based on both pulse energy and average power, with specific calculations accounting for pulse duration, repetition rate, and wavelength. Critical distinction: direct beam viewing hazardous; diffuse reflections generally safe.

Hazard Assessment: Direct beam viewing can cause eye damage including retinal burns with potential for permanent vision impairment. Risk is moderate compared to Class 3B—not instant injury but damage can occur with exposure duration of seconds to tens of seconds. Greater hazard at close range where beam is more concentrated. Specular (mirror-like) reflections may be hazardous depending on reflection angle and distance. Diffuse reflections from typical matte surfaces are generally not hazardous. Not considered a fire hazard except under specialized conditions. Not considered a skin hazard except for prolonged exposure at very close range.

Required Safety Controls: Comprehensive warning labels required: "CAUTION - LASER RADIATION. AVOID DIRECT EYE EXPOSURE." for visible wavelengths, or "CAUTION - LASER RADIATION. AVOID DIRECT EXPOSURE TO BEAM." for invisible wavelengths. Controlled access may be required in some jurisdictions or organizational safety programs. Laser Safety Officer designation recommended for facilities with multiple Class 3R systems or high usage rates. Users should receive specific training on hazards and safe handling. Procedures should require avoiding direct beam viewing and controlling beam paths. Laser safety eyewear is recommended for situations where beam exposure is possible, though not always mandatory under regulations. Engineering controls such as beam stops, enclosed beam paths, and interlocks are recommended but may not be strictly required.

Applications in Telecommunications and Beyond: Higher-power optical transceivers for extended-reach applications when protective housing is removed during service; output from many coherent QPSK and 16-QAM transponders when accessed without enclosure; some DWDM mux/demux ports when measured at output with combined wavelength power; fiber optic test equipment including higher-power OTDRs and light sources; alignment lasers for fiber optic fusion splicing and connector termination; laser levels and alignment tools in construction and surveying; demonstration lasers in educational settings; research laboratory lasers for optical experiments; industrial measurement equipment using laser ranging or profiling; medical diagnostic equipment using laser illumination or scanning. Class 3R is particularly relevant for telecommunications because many modern coherent transceivers contain embedded Class 3R (or higher) lasers that are only accessible when protective housings are opened during authorized service procedures.

The Class 3R Dilemma: Balancing Safety and Operational Practicality

Class 3R presents organizations with a challenging balance between safety and operational practicality. These lasers are hazardous enough to cause injury but are encountered frequently enough in professional environments that overly restrictive controls can impact productivity and may even reduce safety if workers develop "workaround" habits to avoid cumbersome procedures. Best practices suggest implementing tiered controls based on specific use scenarios. For Class 3R lasers in enclosed equipment (such as transceivers and DWDM systems), maintain product-level Class 1 certification through proper housing, interlocks, and automatic power reduction systems, allowing normal operation without special precautions. For Class 3R alignment tools and test equipment where beam must be accessible, implement administrative controls including mandatory training, written standard operating procedures, beam path planning requirements, and designation of controlled work areas with appropriate signage.

The debate over mandatory versus recommended laser safety eyewear for Class 3R represents a microcosm of the broader Class 3R safety dilemma. Some organizations mandate eyewear whenever Class 3R lasers are accessible, while others require eyewear only for prolonged or repeated exposure scenarios, relying on training and administrative controls for brief exposure situations. The rationale for not mandating eyewear in all cases includes: Class 3R power levels are low enough that brief inadvertent exposure is unlikely to cause instant injury, allowing time for the person to move away; appropriate eyewear for specific wavelengths may not always be available in field situations; mandatory eyewear requirements may encourage workers to avoid performing necessary inspections or troubleshooting; and overuse of eyewear for low-risk situations may lead to complacency in high-risk situations where eyewear is truly critical. Organizations must assess their specific risk profile, regulatory environment, and operational requirements to develop appropriate Class 3R safety protocols.

| Class | Power Range (CW, 1550nm) | Hazard Level | Eye Protection Requirements | Typical Telecom Applications |

|---|---|---|---|---|

| Class 1 | 0-10 mW (safely enclosed) | No Hazard | None required during normal use | All standard enclosed transceivers, network equipment, DWDM systems |

| Class 1M | 10-40 mW (divergent beam) | Safe Naked Eye Only | None for naked eye; prohibited to use optical instruments | Disconnected multimode fiber outputs, divergent VCSEL sources |

| Class 1C | Varies by application | Safe in Contact Mode | Per vertical standard requirements | Rarely used in telecom; some specialized contact test equipment |

| Class 2 | Visible only: 0-1 mW | Low Risk | None for brief exposure; avoid deliberate staring | Visible alignment lasers, status indicators (not data transmission) |

| Class 2M | Visible only: 1-4 mW (divergent) | Low Risk | None for brief naked-eye; avoid optical instruments | Visible alignment tools with beam expansion, projection systems |

| Class 3R | 10-50 mW | Moderate Risk | Recommended for extended exposure; mandatory avoid direct viewing | Some coherent transceivers (when housing opened), higher-power alignment tools |

| Class 3B | 50-500 mW | High Risk - Serious Hazard | Required for any potential direct beam exposure | Embedded in coherent systems, EDFA pump lasers (always enclosed) |

| Class 4 | >500 mW (>0.5 W) | Extreme Risk - Maximum Hazard | Always required; additional room-level controls needed | High-power optical amplifiers, specialty systems (always fully enclosed) |

Class 3B: High-Hazard Lasers Requiring Comprehensive Safety Controls

Class 3B lasers represent a substantial escalation in hazard level and required safety measures. These lasers pose serious and immediate dangers to eyes through direct beam viewing or specular (mirror-like) reflections, and at higher power levels within the Class 3B range, they may also present skin hazards from prolonged exposure. The critical distinction between Class 3B and the even more hazardous Class 4 is that diffuse reflections from Class 3B lasers—reflections from matte, non-shiny surfaces—are typically not hazardous, whereas Class 4 diffuse reflections can cause eye injury. This distinction provides some operational flexibility for Class 3B systems compared to Class 4, though extensive safety controls are still mandatory.

For continuous wave lasers, Class 3B encompasses the power range from the upper limit of Class 3R (approximately 5 mW for visible, 50 mW for 1550 nm infrared) up to 500 milliwatts (0.5 watts) regardless of wavelength. This represents a substantial power range—two orders of magnitude—with lasers at the lower end of Class 3B presenting significantly different practical hazards than those at the upper end approaching Class 4 levels. Within telecommunications and optical networking, Class 3B is particularly relevant because many of the embedded laser sources in modern coherent transceivers, optical amplifiers, and high-performance systems operate at Class 3B power levels. These embedded lasers are made safe for field deployment through comprehensive engineering controls including protective housings, electromagnetic or mechanical shutters, key interlocks, automatic power reduction systems, and multiple layers of failsafe mechanisms ensuring Class 1 product-level safety.

Class 3B Technical Specifications and Characteristics

Power Limits: For continuous wave operation: 5 mW to 500 mW for visible wavelengths (400-700 nm); approximately 50 mW to 500 mW for infrared wavelengths in the telecommunications spectrum (1260-1650 nm including 1310 nm and 1550 nm bands). For pulsed lasers, classification depends on complex calculations involving pulse energy, pulse width, repetition rate, and wavelength, with both peak power and average power considered. Upper limit of 500 mW is absolute for CW; pulsed limits vary but are calculated to produce equivalent hazard. Beam divergence and diameter affect classification measurements but not the fundamental power limits.

Hazard Assessment: Severe and immediate eye hazard from direct beam viewing—exposure duration of even a fraction of a second can cause permanent retinal damage including scotomas (blind spots), reduced visual acuity, and potential complete vision loss in affected eye. Specular reflections (from mirrors, polished metal, glass surfaces, or even shiny painted surfaces) are extremely dangerous and must be controlled. At upper power levels (>200 mW), can cause skin burns with prolonged exposure at close range, particularly for darker skin tones that absorb more laser energy. May ignite dark, easily combustible materials (dark paper, cloth) at very close range with sustained exposure, though this is more characteristic of Class 4. Invisible infrared wavelengths present additional danger as there is no visible warning of beam presence and no blink reflex protection.

Required Safety Controls - Extensive and Mandatory: Key-operated interlock required on all access panels to laser enclosure, automatically shutting down laser when panel opened; beam stop or attenuator must be present to terminate beam when not in use; prominent warning labels including "DANGER - LASER RADIATION. AVOID DIRECT EXPOSURE TO BEAM" with specific wavelength and maximum power specified; controlled access areas with warning signs posted at all entrances indicating Class 3B laser use; designated Laser Safety Officer (LSO) required for facilities with Class 3B lasers, responsible for implementing and enforcing safety program; comprehensive training program for all personnel who may be exposed, covering hazards, control measures, emergency procedures, and proper use of protective equipment; laser safety eyewear appropriate for specific wavelengths and power levels, with optical density sufficient to reduce accessible exposure below MPE; eyewear inspection and maintenance program ensuring protective equipment remains effective; standard operating procedures (SOPs) documenting safe setup, operation, alignment, and shutdown procedures; area monitoring or beam path control ensuring accidental exposure is prevented; medical surveillance may be required in some jurisdictions, particularly baseline eye examinations; incident reporting and investigation procedures for any suspected exposures; periodic safety audits to verify continued compliance with all control measures.

Applications in Telecommunications and Industry: Embedded lasers in high-performance coherent transponders using 16-QAM, 64-QAM, or higher modulation formats, which may use 50-200 mW launch power; EDFA (Erbium-Doped Fiber Amplifier) pump lasers operating at 980 nm or 1480 nm wavelengths, typically 100-500 mW; Raman amplifier pump lasers which may use multiple wavelengths each at Class 3B power levels; semiconductor laser diodes used in transceiver manufacturing and testing; fiber laser sources for sensor systems and distributed temperature sensing; optical parametric oscillators and amplifiers in research environments; laser diodes in medical diagnostic equipment including OCT (optical coherence tomography) systems; industrial laser measurement systems for precision ranging and profiling; free-space optical communication transmitters for point-to-point wireless links; laboratory research lasers for photonics and optical communications research; laser sources for fiber Bragg grating writing and fiber processing. Critical point: in deployed telecommunications systems, these Class 3B sources are always enclosed within Class 1 certified equipment, becoming accessible only during authorized service by trained technicians with appropriate safety measures in place.

Class 3B Safety Program Requirements and Implementation

Organizations using Class 3B lasers must establish comprehensive laser safety programs that go far beyond simple warning labels. The foundation of a Class 3B safety program is the designation of a qualified Laser Safety Officer who has received specialized training in laser hazards, control measures, and regulatory requirements. The LSO's responsibilities include conducting hazard assessments for each Class 3B laser installation, developing and implementing standard operating procedures, selecting and specifying appropriate laser safety eyewear, establishing controlled access areas with proper signage, conducting or arranging training for all affected personnel, investigating exposure incidents, maintaining compliance documentation, and serving as the primary point of contact with regulatory authorities regarding laser safety.

Controlled access areas for Class 3B operations require careful design and implementation. At minimum, these areas must be clearly identified with appropriate warning signage at all entrances indicating that Class 3B laser radiation is present, the wavelength(s) in use, and the requirement for protective eyewear. In many cases, physical barriers or administrative controls prevent unauthorized entry. Some high-risk environments implement interlock systems on room entrances that automatically reduce laser power or activate shutters when doors are opened. The controlled area must be designed to contain the beam path, using beam stops, barriers, or enclosures to prevent beam escape beyond the designated hazard zone. All specular reflective surfaces should be eliminated or covered within the controlled area to prevent unexpected hazardous reflections. Laser safety eyewear must be readily accessible at the entrance to controlled areas, with clear indications of which eyewear is appropriate for the specific wavelengths in use.

Laser Safety Eyewear Selection and Use for Class 3B

Proper selection, use, and maintenance of laser safety eyewear is critical for Class 3B applications. Eyewear must be selected based on the specific wavelength(s) present, with optical density (OD) sufficient to reduce the maximum expected exposure to below the Maximum Permissible Exposure (MPE) for the eye. As a general guideline, Class 3B applications typically require eyewear with OD 4 to OD 6 depending on the specific power level and wavelength. The required OD can be calculated using the formula: OD = log10(P_max / MPE × Area), where P_max is the maximum expected power incident on the eyewear and Area is the beam area at the eyewear surface.

Critical considerations for laser safety eyewear include: wavelength specificity—eyewear must be rated for the specific wavelength(s) in use, not just "generally for lasers"; optical density verification—ensure the specified OD is adequate for maximum expected exposure conditions including direct beam or strong specular reflections; visible light transmission—eyewear should provide adequate visible light transmission (VLT) to allow safe work performance, typically 20% minimum; optical quality—eyewear should not introduce distortion that impairs the user's ability to perform tasks safely; physical protection—eyewear must provide side shields and should meet impact resistance standards (such as ANSI Z87.1); comfort and fit—eyewear must fit properly and comfortably to encourage consistent use; marking and identification—all laser safety eyewear must be clearly marked with wavelength range, optical density rating, and applicable standards; inspection and maintenance—implement regular inspection program to identify scratched, cracked, or degraded eyewear that no longer provides adequate protection; prescription compatibility—provide prescription laser safety eyewear or fit-over styles for users who require vision correction; spare eyewear—maintain adequate spares to accommodate visitors and account for lost or damaged eyewear.

A common misconception about Class 3B is that if you're using laser safety eyewear, you can look directly at the beam. This is categorically false and extremely dangerous. Laser safety eyewear is designed to provide protection from inadvertent exposure, reflections, or scattered light—not from deliberately staring into a direct Class 3B beam. Even with appropriate eyewear, the best practice is to avoid all direct beam exposure through proper beam path control, use of beam stops and blockers, and administrative procedures that never require personnel to place their eyes in potential beam paths. Eyewear is the last line of defense, not a license for careless practices. Additionally, no laser safety eyewear provides protection across all wavelengths simultaneously. If working with multiple laser sources at different wavelengths, either use eyewear rated for all wavelengths present (which may significantly reduce visible light transmission), or implement procedures ensuring only one wavelength is active at a time and appropriate eyewear is worn for that specific wavelength.

Class 4: Highest Hazard Classification Requiring Maximum Safety Controls

Class 4 represents the highest and most hazardous laser classification, encompassing all lasers that exceed Class 3B limits. These high-power lasers are capable of causing severe and immediate eye damage from both direct beam exposure and diffuse reflections from any surface, making them extraordinarily dangerous in uncontrolled environments. Class 4 lasers also present substantial skin burn hazards, fire hazards (capable of igniting combustible materials including paper, cloth, plastic, and wood), and can generate hazardous airborne contaminants when interacting with target materials through vaporization, creating toxic fumes or particles. The multi-faceted hazard profile of Class 4 lasers necessitates the most comprehensive safety controls in the laser safety classification system, often requiring dedicated facilities designed specifically for high-power laser operations.

For continuous wave operation, Class 4 includes any laser with accessible emission exceeding 500 milliwatts (0.5 watts). There is no upper limit to Class 4—the classification encompasses lasers from just over half a watt to industrial cutting lasers operating at tens of kilowatts and beyond. This enormous power range means that specific hazards and required controls can vary dramatically within Class 4, with a 1-watt laser presenting a very different risk profile than a 10-kilowatt industrial processing laser. However, all Class 4 lasers share the fundamental characteristics of being hazardous through multiple exposure pathways (direct beam, specular reflections, diffuse reflections, skin contact, fire ignition) and requiring the most stringent safety controls available. In the telecommunications and optical communications industry, Class 4 lasers are found in high-power optical amplifiers (multi-watt EDFAs and Raman amplifiers), high-power pump laser sources for amplification stages, specialized fiber lasers for nonlinear optics research, and ultra-high-power free-space optical communication systems for extreme long-distance links.

Class 4 Technical Specifications and Characteristics

Power Limits: Exceeds 500 milliwatts (0.5 watts) for continuous wave operation. No upper limit—Class 4 encompasses everything from 501 mW research lasers to multi-kilowatt industrial systems to megawatt military and scientific lasers. For pulsed lasers, classification is based on exceeding Class 3B limits for either pulse energy, average power, or both. Within telecommunications, typical Class 4 applications range from approximately 0.5 watts to 10+ watts for optical amplifiers, though specialized research systems may exceed these levels. Beam characteristics (divergence, diameter) don't change the fundamental classification if power exceeds 500 mW, though they affect specific hazard ranges and required control measures.

Hazard Assessment - Extreme and Multi-Faceted: Immediate and severe eye damage from direct beam exposure—can cause instant permanent blindness, retinal scarring, or complete retinal detachment with exposure duration measured in milliseconds. Diffuse reflections (from matte surfaces, paper, painted walls, clothing, skin) are hazardous—this is the critical distinction from Class 3B. Can cause immediate retinal damage even from diffusely scattered light, not just specular reflections. Specular reflections are catastrophically dangerous, potentially equivalent to direct beam exposure. Severe skin burns possible with even brief exposure, particularly at higher power levels—can cause third-degree burns, tissue charring, and permanent scarring. Ignition of combustible materials including paper, fabric, plastic, wood, and some metals at sufficient power levels—presents serious fire hazard requiring fire suppression systems. Generation of hazardous airborne contaminants when beam interacts with materials—can produce toxic fumes, particulates, or vapors requiring ventilation systems. Electrical hazards from high-voltage power supplies (multi-kilowatt systems may use dangerous voltage and current levels). Invisible infrared beams provide no visual warning and no protective aversion response, compounding all other hazards. Plasma formation at very high power levels (>kW) can produce UV radiation, X-rays, and explosive shock waves requiring additional protective measures.

Required Safety Controls - Most Stringent and Comprehensive: All Class 3B controls plus numerous additional requirements. Multiple redundant interlocks on all access points to laser enclosure—primary, secondary, and sometimes tertiary interlocks ensuring laser cannot operate when enclosure is breached. Key-operated master control requiring special authorization for system operation. Emergency stop controls (panic buttons) at multiple locations including all exits from laser controlled area, immediately shutting down laser power. Beam enclosure or clearly defined, physically delimited beam path preventing any possibility of human exposure under normal operation. Permanent beam stops at beam termination points, rated for full laser power without degradation. Room design considerations including non-reflective surface treatments (anodized metal, matte black paint) to eliminate specular reflections, controlled room access with interlocked entry doors that reduce laser power or activate shutters when opened, warning lights (typically red beacon) outside entrances indicating when laser is operational, area classification as "laser controlled area" with posted signs and access restrictions, and elimination of windows or installation of laser-blocking window coverings preventing beam escape from designated area. Mandatory high-quality laser safety eyewear for all personnel in controlled area, with OD typically 5-7 depending on power and wavelength, enforced through administrative controls and potentially physical access controls (eyewear required to enter). Special protective clothing may be required for very high-power systems, including fire-resistant lab coats and gloves. Comprehensive training program covering all hazards, control measures, emergency procedures, and incident response, with annual refresher training and documented competency assessments. Designated Laser Safety Officer with extensive training and authority to halt operations if safety concerns arise. Written standard operating procedures for all laser operations including startup, normal operation, alignment procedures, shutdown, and emergency response. Medical surveillance program including baseline eye examinations and periodic re-examinations for all personnel regularly working with Class 4 lasers. Fire suppression equipment readily accessible, with personnel trained in its use. Fume extraction and ventilation systems if laser will interact with materials, designed to capture and filter/exhaust airborne contaminants. Area monitoring systems (beam detectors, smoke detectors, temperature sensors) providing early warning of hazardous conditions. Strict beam path control during any alignment procedures, including use of beam profilers, cameras, and viewing cards rather than direct observation. Lock-out/tag-out procedures for maintenance activities requiring entry into normally protected areas. Thorough incident investigation procedures for any actual or suspected exposure, near-misses, or safety system failures. Periodic comprehensive safety audits by qualified laser safety professionals, verifying all controls remain effective.

Applications Across Industries - High-Power Systems: High-power optical amplifiers for long-haul submarine telecommunications systems—multi-watt EDFAs providing gain for transoceanic fiber links. Distributed Raman amplification systems using multiple high-power pump lasers along fiber span. High-power pump laser modules at 980 nm or 1480 nm for amplifier stages—individual pumps may approach or exceed Class 4 thresholds, and combined pump power regularly exceeds Class 4. Fiber laser sources for industrial material processing including cutting, welding, and marking—can range from watts to tens of kilowatts. Medical surgical laser systems for procedures including laser eye surgery (LASIK), tumor ablation, and cosmetic treatments. Scientific research lasers including ultrafast (femtosecond/picosecond) lasers for nonlinear optics research, fiber lasers for spectroscopy and sensing, and experimental free-space optical communication testbeds. Military and defense laser systems for range-finding, target designation, directed energy weapons, and secure communications. Entertainment industry high-power laser projection systems—laser light shows use Class 4 sources with sophisticated beam control. Industrial measurement and processing systems including laser-based additive manufacturing (3D printing), laser surface treatment and hardening, and precision cutting systems for aerospace and automotive industries. Research laboratory fiber laser amplifiers for telecommunications equipment testing and characterization. Very high-power laser diode arrays for pumping solid-state lasers or direct application. Specialized free-space optical communication systems for satellite links or extreme long-distance terrestrial systems.

Class 4 Facility Design and Room-Level Safety Controls

Class 4 laser facilities require comprehensive engineering at the room level, not just at the equipment level. The facility design process begins with careful site selection, ideally choosing locations where laser-controlled areas can be isolated from general building traffic, minimizing the number of people potentially exposed to hazards. Room layout should provide a dedicated entrance with anteroom or buffer zone where safety equipment is donned and procedures reviewed before entering the laser area. The laser room itself should have minimal windows, or windows must be covered with laser-blocking materials or shutters; glass windows can transmit certain laser wavelengths and may create unexpected hazardous reflections. Interior wall surfaces should be treated with non-reflective coatings or coverings—anodized aluminum, matte black paint, or specialized laser-absorbing materials—to minimize scattered reflections. Optical tables or benches should be positioned to keep primary beam paths away from normal traffic patterns within the room.

Entrance doors to Class 4 laser areas must incorporate safety interlocks that either reduce laser power to below hazardous levels or activate beam shutters when doors are opened. These interlocks should be redundant (dual interlock switches on each door) and fail-safe (defaulting to safe condition if power lost or switch fails). Warning lights (typically rotating red beacons) must be mounted outside all entrances, illuminated whenever Class 4 lasers are operational within. Clear signage must identify the area as a laser-controlled zone, specify Class 4 hazards, indicate wavelength(s) present, and list safety requirements including mandatory eyewear. Some facilities implement card-reader or biometric access controls, restricting entry to trained, authorized personnel only. Emergency exits must be clearly marked and equipped with panic hardware, but must also incorporate interlocks that trigger laser shutdown or shutter closure when emergency exit is used, preventing personnel from fleeing through an active beam path during an emergency.

Ventilation systems for Class 4 areas require special attention, particularly for systems that will interact with materials (cutting, engraving, ablation). Fume extraction should provide local capture at the point of laser-material interaction, with ducts routing contaminated air to appropriate filtration systems before exhaust. For very high power systems or those processing materials that generate toxic fumes, dedicated fume hoods may be required, with airflow designed to maintain slight negative pressure in the laser area relative to surrounding spaces. Fire suppression systems must be evaluated carefully—while sprinkler systems are necessary for life safety, water spray into high-power laser areas creates special hazards including electrical shock risks and potential for steam generation. Some Class 4 facilities use clean-agent suppression systems (FM-200, Novec 1230) as an alternative or supplement to water sprinklers, providing rapid fire suppression without water damage concerns. Electrical power distribution should provide emergency stop circuit that kills power to all laser sources simultaneously, with emergency stop buttons mounted at strategic locations including all exits and multiple locations within the laser area.

Special Considerations for Telecommunications Class 4 Applications

Within the telecommunications and optical networking industry, Class 4 lasers are typically found only in specialized environments rather than general deployment. Manufacturing facilities producing optical amplifiers or high-power transceivers work with Class 4 sources during assembly and testing, requiring comprehensive Class 4 safety programs. Research and development laboratories investigating next-generation coherent technologies, nonlinear fiber optics, or ultra-long-haul transmission systems regularly use Class 4 fiber lasers and amplifiers. Network operations centers for submarine cable systems may have Class 4 amplifier modules accessible during maintenance, though these are typically enclosed within Class 1 certified systems during normal operation. Testing facilities characterizing fiber optic components at high power levels may expose Class 4 sources during controlled test procedures.

A critical distinction for telecommunications applications is that virtually all fielded equipment containing Class 4 sources is designed, tested, and certified as Class 1 at the product level. A coherent transponder containing a 2-watt optical output stage (Class 4 source) is engineered with sufficient protective housings, interlocks, shutters, and automatic power reduction systems to achieve Class 1 product certification, meaning field technicians installing or maintaining the transponder never encounter Class 4 exposure levels. The Class 4 source only becomes accessible if authorized service personnel deliberately defeat multiple interlocks and open protective housings according to factory service procedures—a scenario where the technician has received extensive training, is working in a controlled environment, and understands the Class 4 hazards. This embedded-laser approach allows the telecommunications industry to deploy high-power optical systems safely in general network environments without requiring every installation site to meet Class 4 facility requirements.

Organizations procuring telecommunications equipment should verify that any systems containing high-power sources carry proper Class 1 product certification from accredited testing laboratories. Service procedures for equipment containing embedded Class 4 sources should explicitly document the laser hazards, specify required safety precautions including mandatory laser safety eyewear, and be restricted to personnel who have completed Class 4 laser safety training. Some organizations maintain dedicated service areas meeting Class 4 facility requirements for performing any service activities that may expose embedded Class 4 sources, rather than attempting such service in the field. Equipment should be designed such that routine maintenance tasks (replacing failed components, upgrading software, cleaning connector end-faces) can be performed without accessing embedded high-power laser sources, reserving Class 4 exposure scenarios for rare factory-level repair procedures.

Interactive Safety Simulators

Laser Classification Calculator

Determine the appropriate laser safety class based on wavelength, output power, and beam characteristics.

Maximum Permissible Exposure & NOHD Calculator

Calculate safe exposure limits and nominal ocular hazard distances.

Optical Power Budget Safety Analyzer

Analyze cumulative optical power from multiple wavelengths for DWDM systems.

Safety Compliance Assessment Tool

Evaluate comprehensive safety requirements based on laser classification.

Key Takeaways

Note: This guide is based on IEC 60825-1:2014, 21 CFR 1040.10/11, industry standards, and real-world implementation experiences. Specific requirements may vary based on equipment, jurisdiction, and regulatory updates. Always consult qualified laser safety officers and follow current regulations in your region. Laser safety requirements are subject to change; verify current standards before implementation.

For educational purposes in optical networking and DWDM systems

Unlock Premium Content

Join over 400K+ optical network professionals worldwide. Access premium courses, advanced engineering tools, and exclusive industry insights.

Already have an account? Log in here