29 min read

ROV Operations in Subsea Cable Installation

Underwater Robotics for Cable Burial, Inspection, and Repair in Modern Submarine Networks

Introduction

Remotely Operated Vehicles (ROVs) represent essential technology for deploying, maintaining, and repairing subsea optical cable systems. These sophisticated underwater robots perform tasks impossible or prohibitively expensive through traditional methods, operating at depths from shallow coastal waters to beyond 3,000 meters. ROVs execute multiple critical functions throughout the cable system lifecycle: pre-installation route inspection, post-lay burial operations, cable manipulation during installation, fault location and repair, and periodic system inspection. The technology bridges the gap between surface vessel capabilities and the underwater environment where submarine cables operate.

This article addresses the technical architecture, operational procedures, and practical considerations for ROV deployment in submarine cable projects. Engineers responsible for cable installation planning, maintenance operations, or marine coordination will gain understanding of vehicle selection criteria, operational workflows, environmental constraints, and integration requirements with cable ship systems. The content builds from fundamental ROV design principles through advanced operational scenarios, providing reference material applicable to both new installations and repair operations across diverse marine environments.

Fundamental Principles and Historical Context

The application of submersible equipment in submarine cable operations emerged from the need to protect cables from external damage, particularly fishing activity that became increasingly mechanized through the mid-20th century. As cable systems extended into deeper waters and more challenging environments, the constraints of surface-deployed equipment became apparent. Towed ploughs, while effective for simultaneous cable laying and burial, cannot operate in all seabed conditions and lack the precision required for repair operations or work near existing infrastructure.

ROVs address these constraints by providing underwater mobility independent of surface vessel movement. Unlike towed systems that must maintain constant forward motion, ROVs can hover, reverse, and make precise adjustments to position. This maneuverability enables operations in areas with complex bathymetry, high currents, or existing infrastructure where ploughs cannot safely operate. The vehicle remains connected to the surface vessel through an umbilical cable that delivers power and control signals while transmitting telemetry and video data to operators.

Historical Development: The transition from manned submersibles to ROVs represented a significant safety and economic improvement. Early cable burial operations sometimes employed manned submarines, exposing divers to considerable risk. The introduction of the Submersible Craft Assisting Repair and Burial (SCARAB) in 1976 marked a significant advancement, demonstrating that remotely controlled vehicles could effectively handle cable burial and repair tasks. ROV technology eliminated human danger while providing superior operational endurance and depth capability. First commercial ROV operations for cable work demonstrated reliability that exceeded expectations, leading to rapid adoption across the industry.

Modern cable ships carry ROV systems as standard equipment, with many vessels capable of operating multiple vehicle types. The choice between ROV-based operations and other methods depends on water depth, seabed composition, burial requirements, environmental conditions, project timeline, and available vessel capabilities. In shallow water installations, tracked ROVs may compete with or complement shore-based trenching equipment. In deep water beyond practical plough operating depth, ROVs provide the only viable method for inspecting and repairing installed systems.

Comparison with Plough-Based Operations

The relationship between ROV operations and plough-based burial is complementary rather than competitive. Ploughs excel at simultaneous cable laying and burial in suitable seabed conditions, achieving burial depths up to 3 meters while the cable ship maintains forward speed. However, ploughs face constraints in rocky seabeds, areas with steep gradients, locations with existing infrastructure, and situations requiring precise cable placement. Plough operations also require continuous cable tension that may stress optical fibers near their mechanical limits.

ROVs perform post-lay burial in areas where ploughs cannot operate, conduct repair cable burial after maintenance operations, handle inspection and manipulation tasks requiring precision positioning, and operate in environmental conditions that would prevent plough deployment. Most modern cable installations employ a hybrid approach, using ploughs for the majority of burial work while relying on ROVs for challenging sections and post-installation operations. This strategy optimizes both installation speed and protection completeness across the entire cable route.

Technical Architecture and System Design

ROV systems for submarine cable operations comprise several integrated subsystems, each critical to successful underwater operations. The primary vehicle contains propulsion systems, power distribution, sensor packages, tool interfaces, and structural framework. The umbilical connection to the surface vessel provides power delivery (typically 600 to 900 kilowatts for large systems) and bidirectional communication for control signals, telemetry, and video transmission. Surface systems include control consoles, power generation and conditioning equipment, umbilical management systems, and launch and recovery mechanisms.

Vehicle Classification by Propulsion Architecture

Submarine cable ROVs fall into three main design categories based on propulsion and trenching methodology. Each design offers distinct advantages for specific operational scenarios, and the selection depends on water depth, seabed conditions, burial requirements, and available ship capabilities.

Thruster-based ROVs use hydraulic or electric thrusters for all motive power during both swimming and trenching operations. This design typically incorporates eight thrusters providing horizontal, vertical, and lateral drive capability. The thruster configuration enables operation in soft seabed conditions where track-based systems would lack traction, allows precise positioning during manipulation tasks, and provides superior maneuverability in complex underwater environments. These vehicles can operate in sea currents exceeding 1.5 knots and do not depend on seabed support for forward motion. Power requirements typically range from 600 to 900 kilowatts. Thruster-based designs represent the most versatile ROV configuration but require substantial power delivery through the umbilical system and consume more energy than alternative designs.

Hybrid thruster and track ROVs combine thrusters for swimming with tracks or skids for trenching operations. This design offers greater trenching capability in harder seabed materials compared to pure thruster systems while maintaining good maneuverability during transit. The tracks provide improved stability during burial operations and enable use of more aggressive cutting tools including rock wheels and chain cutters. Power requirements in tracked mode are lower than for purely thruster-dependent operations. However, track effectiveness depends on seabed load-bearing capacity, limiting use in very soft sediments where the vehicle would sink rather than achieve traction. These systems typically weigh more than pure thruster designs, ranging from 8 to 17 tons in air, which influences launch and recovery procedures.

Track-only ROVs rely exclusively on mechanical tracks for propulsion during trenching, though they may use thrusters for initial descent and recovery phases. This design suits shallow water operations where the seabed can support vehicle weight and where aggressive trenching through rock or hard materials is required. Track-only systems achieve excellent stability for cutting operations and consume less power than continuously operating thrusters. The primary constraint involves reduced mobility in soft sediments and inability to operate effectively in strong currents when not in contact with the seabed. Operating depth typically limits to 1,000-1,500 meters due to the mechanical complexity of track systems under pressure.

ROV Propulsion System Comparison

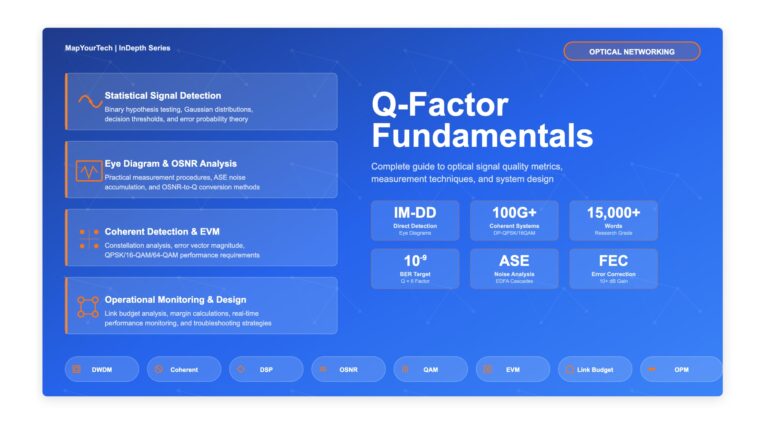

Figure 1: Three main ROV propulsion designs with operational characteristics and ideal applications

Trenching and Burial Systems

Cable burial represents the primary function for most submarine cable ROVs. The burial mechanism varies by vehicle design and operational requirements. Water jetting systems remain the most common burial technology, using high-pressure water jets to fluidize seabed sediments. The ROV straddles the laid cable, injecting water to create a temporary trench while a cable depressor arm guides the cable into the excavation. As the vehicle advances, disturbed sediment settles back over the cable, achieving burial depths typically between 1 and 3 meters depending on seabed conditions and vehicle capability.

Mechanical cutting systems employ rock wheels or chain excavators for harder substrates where water jetting proves ineffective. Rock-cutting wheels rotate against the seabed, grinding through consolidated materials to create a trench path. Chain cutters use a continuous chain with cutting teeth, similar to a mechanized trencher. These systems enable burial in rock, coral, and heavily consolidated sediments but consume significantly more power and operate at slower speeds than jetting systems. The choice between jetting and mechanical cutting depends on geotechnical survey results that characterize seabed composition along the cable route.

Burial Depth Capability: Modern ROVs can achieve burial depths exceeding 3 meters in favorable conditions, matching the performance of towed ploughs. This capability ensures that cable repaired at sea can be buried to the same protection depth as originally installed cable, maintaining consistent system protection throughout the route. Burial depth depends on seabed composition, with cohesive materials generally allowing deeper burial than loose, non-cohesive sediments. Operating parameters including jetting pressure, vehicle speed, and cable slack must be optimized for each seabed type encountered.

Sensor and Detection Systems

ROV sensor suites provide situational awareness and enable precise cable interaction. High-definition cameras with LED illumination arrays offer visual feedback to operators, revealing cable position, seabed conditions, and potential obstacles. Multiple camera views including forward, downward, and side-facing perspectives give operators comprehensive environmental awareness during operations. Camera systems must withstand hydrostatic pressure at maximum operating depth while maintaining optical clarity through protective viewports.

The Tone Signal System (TSS) provides cable detection capability through magnetic field sensing. When the cable carries an electroding tone applied from a shore station, the TSS detects the resulting magnetic field, guiding the ROV to follow the cable route even when visual contact is impossible due to burial or poor water clarity. This system proves essential during repair operations when locating buried or damaged cable sections. The TSS sensitivity determines detection range, typically several meters depending on tone signal strength and environmental electromagnetic interference.

Sonar systems serve multiple functions including beacon tracking for vehicle position relative to the surface vessel, obstacle detection for collision avoidance, and seabed profiling to assess bathymetry and burial conditions. Attitude sensors monitor vehicle orientation, depth transducers measure operating depth, and environmental sensors track water temperature and other parameters relevant to operations. The integration of these sensor inputs through the vehicle control system enables operators to maintain precise position and heading even in challenging environmental conditions.

Manipulation and Tool Systems

Cable manipulation requires specialized tooling integrated with the ROV platform. Mechanical manipulator arms, typically hydraulically actuated with multiple degrees of freedom, enable the ROV to grasp, lift, and position cable during repair and installation operations. Modern manipulator designs provide force feedback to operators, preventing excessive grip pressure that could damage cable structure. Cable cutters, either hydraulic shears or explosive-actuated devices, allow separation of cable sections during fault isolation. Cable grippers provide controlled lifting capability without damaging the cable structure, using shaped jaws that distribute load over sufficient cable length.

The cable depressor represents a critical tool during burial operations, consisting of a shaped arm or roller that guides cable into the trench created by jetting or cutting systems. Proper depressor design ensures the cable enters the trench without exceeding minimum bend radius specifications (typically 3 meters for submarine cables) and without creating loops or kinks that would compromise optical performance. The depressor must maintain consistent cable positioning as the ROV advances, compensating for vehicle pitch and roll induced by thrusters or seabed interaction.

ROV System Architecture

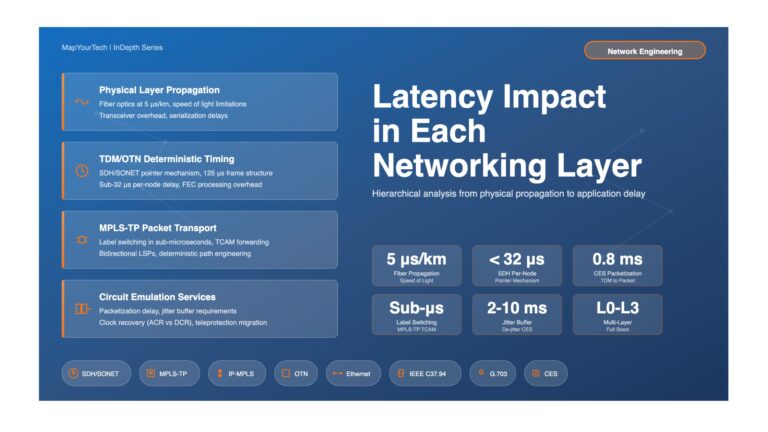

Figure 2: ROV system architecture showing umbilical connection, power delivery, and integrated subsystems

Operational Behavior and Procedures

ROV deployment for submarine cable work follows established procedures designed to ensure operational safety and effectiveness. The operational sequence varies by mission type but shares common elements across all ROV activities. Proper coordination between ROV operators, cable ship bridge crew, and project management remains essential throughout operations.

Launch and Recovery Operations

Modern cable ships employ Launch and Recovery Systems (LARS) to deploy and retrieve ROVs in challenging sea conditions. A LARS typically consists of a large A-frame structure mounted at the vessel stern, a lift wire system with redundant safety features, and motion compensation equipment to reduce dynamic loading during launch and recovery. The A-frame extends beyond the vessel stern, positioning the ROV over open water before lowering begins. This arrangement protects both the vehicle and vessel from collision during the critical transition through the splash zone where wave action imposes significant forces.

During launch, the ROV secures to the A-frame while initial system checks verify that all subsystems function correctly. The vehicle then descends through the splash zone where wave action can impose significant forces on both the ROV and lift wire. Motion compensation systems actively adjust wire tension to minimize shock loads. Once clear of surface wave effects, the ROV transitions to powered descent using its own thrusters while umbilical cable pays out from dedicated winches. Operators monitor descent rate, vehicle attitude, and umbilical management throughout the deployment sequence.

Recovery reverses this sequence but demands greater caution due to ROV weight and potential seabed material accumulation on the vehicle. The ROV first swims clear of the seabed, then transitions to lift wire support for ascent through the water column. Surface crews monitor vehicle ascent rate, umbilical tension, and vessel motion to optimize recovery timing. The LARS motion compensation system remains active throughout recovery, reducing dynamic loads that could damage equipment or endanger personnel. Advanced LARS capabilities extend operational weather windows compared to crane-based launch and recovery, which requires nearly calm conditions for safe ROV handling.

Post-Lay Inspection and Burial

Post-lay inspection and burial (PLIB) represents a common ROV mission profile. After surface laying of cable in areas unsuitable for plough burial, or in sections deliberately skipped during ploughing operations, ROVs return to bury exposed cable. The PLIB operation begins with the cable ship positioning itself at the start of an unburied cable section. ROV deployment follows standard launch procedures, after which the vehicle swims or descends to the seabed near the cable location.

Using TSS or visual navigation, the ROV locates the surface-laid cable and positions itself to straddle the cable route. The burial tool activates and the ROV advances along the cable path, creating a trench and guiding cable into the excavation. Operators monitor burial depth, vehicle heading, and cable position throughout the operation. The ROV burial rate depends on seabed conditions, power availability, and required burial depth, typically ranging from several hundred meters to over a kilometer per dive. Continuous communication between ROV pilots and cable ship bridge enables real-time adjustments to vessel position maintaining optimal cable geometry.

Successful PLIB requires careful slack management during initial cable laying. Insufficient slack prevents the ROV from pushing cable into the trench without applying excessive tension that could damage optical fibers. Excessive slack creates cable loops that complicate ROV navigation and burial operations. Industry practice typically specifies slack values less than 1 percent for PLIB sections, providing enough cable movement for burial while maintaining route geometry. The cable engineer must calculate slack requirements based on seabed profile, burial depth, and ROV operational characteristics.

ROV Cable Burial Process

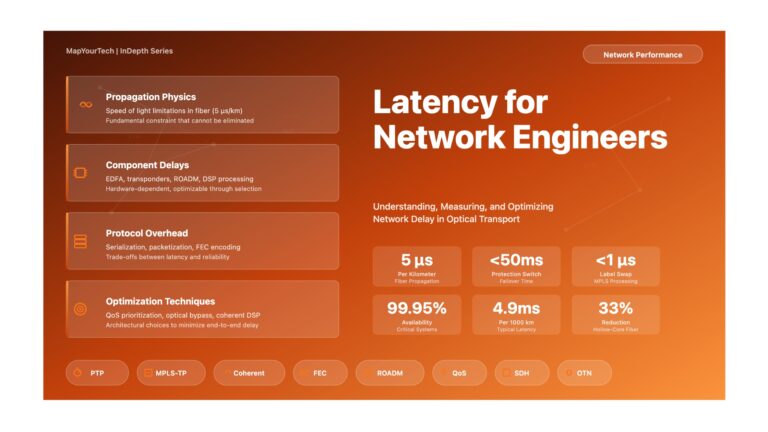

Figure 3: Cable burial operation showing water jetting process and cable depressor guiding cable into trench

Cable Repair Operations

ROV involvement in cable repair spans multiple operational phases. When fault location indicates a damaged cable section, the repair operation begins with cable recovery using grapnels deployed from the cable ship. However, in areas where the cable has been buried, ROVs must first detrench the cable before grapnel recovery becomes possible. This detrenching operation employs specialized grapnel designs or direct ROV excavation to expose sufficient cable length for recovery operations.

The ROV positions over the buried cable and uses its burial tool in reverse mode, excavating sediment to expose the cable. Once exposed, the cable ship deploys grapnels to lift and recover the cable for repair. Following splice completion and reinstatement of the repaired cable section, the ROV returns to rebury the repair to match the surrounding cable protection level. This ensures consistent mechanical protection across the entire cable route, preventing the repair section from becoming a weak point susceptible to external aggression.

ROVs also perform direct cable manipulation during repair operations. The manipulator arms can lift cable onto the vehicle for cutting operations, separate cable ends to create working space for splice operations, and position cable during final splice laydown. In shallow water repairs, the ROV may remain on station throughout the jointing process, monitoring cable position and maintaining proper geometry to prevent excessive bending or stress on the splice.

Inspection and Survey Operations

Routine inspection missions verify cable burial status, identify areas requiring attention, and document system condition. The ROV follows the cable route using TSS guidance, recording video of cable exposure, seabed disturbances, and potential hazards. Sonar sensors measure burial depth where cable remains below the seabed surface, building a comprehensive assessment of route protection. Inspection frequency depends on environmental risk factors including fishing activity intensity, seabed mobility, and historical fault patterns.

Survey operations may also support new cable installations by verifying route conditions, confirming clearance from existing infrastructure, and documenting crossing points where multiple cables intersect. The ROV provides ground-truth validation of side-scan sonar data collected during initial route surveys, resolving ambiguities in seabed features or existing cable positions. This information feeds back into route engineering decisions and burial requirement specifications.

Performance Considerations and Trade-offs

ROV operations face inherent constraints and challenges that affect mission planning and execution. Understanding these limitations enables realistic project scheduling and appropriate risk mitigation. Performance optimization requires balancing multiple competing factors including operational speed, power consumption, environmental tolerance, and equipment longevity.

Environmental Operating Constraints

Sea state and current conditions directly impact ROV operations. While modern ROVs can work in current speeds exceeding 1.5 knots, higher flows increase power consumption, reduce burial effectiveness, and complicate vehicle navigation. Strong cross-currents push the vehicle off course, requiring constant operator correction and reducing forward progress. Surface wave action affects launch and recovery operations even when subsurface conditions remain acceptable for ROV work. The relationship between surface conditions and underwater environment depends on water depth, with deeper operations experiencing less influence from surface weather.

Water clarity influences operations requiring visual navigation or inspection. Suspended sediment from previous burial operations, biological activity, or disturbed bottom conditions reduces camera effectiveness. While TSS provides cable tracking independent of visibility, many tasks including connector manipulation and detailed inspection require adequate visual range. Seasonal variations in water clarity affect project scheduling, particularly in coastal environments with variable turbidity driven by river discharge or algal blooms.

Seabed composition constrains burial capability and operational approach. Rocky substrates require mechanical cutting systems that operate more slowly than water jetting and consume substantial power. Very soft sediments may not provide adequate support for tracked vehicles. Stratified seabeds with hard layers underlying softer surface sediments can limit achievable burial depth even with powerful cutting equipment. Geotechnical survey data characterizing seabed composition proves essential for accurate ROV capability assessment and operational planning.

Power and Endurance Limitations

Umbilical cable length and power transmission capacity limit ROV working range and capability. Electrical resistance in long umbilical runs reduces delivered voltage at the vehicle, constraining available power for propulsion and tools. Most ROV umbilicals extend 2,000 to 3,000 meters, limiting operations to relatively shallow water compared to maximum cable system depths exceeding 8,000 meters. Extended-range operations require larger diameter umbilicals with associated handling challenges and increased weight that affects vessel stability.

Mission duration depends on multiple factors including operator endurance, equipment wear, and consumable depletion. While the ROV itself can operate continuously given adequate power, practical considerations limit single-dive duration. Operators experience fatigue after several hours of concentrated control activity, equipment seals and bearings accumulate wear, and hydraulic fluid temperatures rise under continuous operation. Most cable operations plan ROV dives lasting 8 to 16 hours, with recovery for inspection and maintenance between missions. Extended operations may employ shift-based operation with multiple pilot teams.

Coordination and Integration Challenges

ROV operations require careful coordination with surface vessel activities. The umbilical cable creates an obstruction that can foul propellers, interact with cable being laid or recovered, and complicate vessel maneuvering. When cable operations and ROV deployment must occur simultaneously, separate vessels may be required to avoid interference. This increases project cost and complexity but provides operational flexibility for time-critical activities such as emergency repairs.

Safety considerations govern all ROV operations. The umbilical represents a single point of failure—if severed or damaged, the ROV becomes stranded on the seabed. Proper umbilical maintenance programs reduce this risk but cannot eliminate it entirely. Power delivery through the umbilical presents electrical hazards both to personnel and to the cable system being worked. Safety protocols isolate ROV power from cable power feeds and require equipment lockout during certain operations. Personnel training emphasizes electrical safety and emergency procedures for umbilical failures.

Performance Comparison with Alternative Methods

ROV burial rates lag behind plough performance in favorable conditions. While a plough may bury several kilometers of cable per day when conditions permit continuous operation, ROV operations typically achieve several hundred meters to perhaps 1 kilometer per day depending on conditions. This performance difference makes ROVs economically suitable for specific applications rather than primary burial across entire cable routes. However, ROVs access areas physically impossible for ploughs, providing capability that justifies the lower productivity in challenging sections.

Tool integration presents ongoing challenges. While ROVs excel at standard burial and inspection tasks, specialized operations may require custom tooling that must be designed, tested, and integrated with the vehicle. The development timeline for specialized tools can delay projects if requirements emerge late in planning. Maintaining tool inventory across a fleet of vehicles requires significant capital investment and storage capacity aboard cable ships with limited deck space.

Emerging Technology: Autonomous Underwater Vehicles (AUVs) represent an evolution beyond tethered ROVs. These untethered platforms can survey cable routes and inspect installed systems without the range limitation of an umbilical connection. However, AUVs lack the manipulation capability and power delivery of ROVs, limiting their role to inspection and survey rather than intervention activities. The technology continues to mature with potential for broader application in routine inspection missions where direct intervention is not required. AUVs employ pre-programmed mission plans or semi-autonomous behavior, though remote monitoring and control modification remains possible through acoustic communication links.

Practical Applications and Use Cases

Effective ROV deployment requires careful planning that considers equipment capabilities, environmental factors, and project objectives. The selection of appropriate ROV type and configuration directly affects project success, schedule reliability, and cost outcomes. Several practical factors influence operational success and should guide project planning from initial route survey through final acceptance testing.

Vehicle Selection Methodology

Matching ROV capabilities to project requirements begins with assessing operational scenarios. Water depth requirements determine vehicle depth rating and influence power delivery infrastructure design. Seabed conditions indicated by geotechnical surveys guide burial tool selection, with jetting tools for soft sediments and cutting systems for hard substrates. Expected environmental conditions including current regime and wave climate affect vehicle design requirements and operational weather windows.

The following table summarizes typical ROV specifications for submarine cable operations:

| Parameter | Thruster-Based ROV | Hybrid ROV | Track-Based ROV |

|---|---|---|---|

| Weight in Air | 4-8 tons | 8-17 tons | 10-17 tons |

| Maximum Depth | 2000-2500 m | 2000-3000 m | 1000-1500 m |

| Power Requirement | 600-900 kW | 300-600 kW | 200-400 kW |

| Typical Burial Depth | 1-2 m | 2-3 m | 1-2.5 m |

| Optimal Application | Soft seabed, strong currents | Variable seabed, deep water | Hard seabed, shallow water |

Crew Training and Operational Experience

ROV operations depend heavily on skilled personnel. Pilot proficiency affects operational efficiency, equipment safety, and mission success rate. Experienced pilots develop intuitive understanding of vehicle behavior, anticipate problems before they become critical, and optimize work patterns for efficiency. Training programs combine classroom instruction on system operation with supervised practical experience under progressively challenging conditions. Simulator training enables skill development without equipment risk or operational cost.

Support personnel including supervisors, technicians, and deck crew also require specialized training. Umbilical management demands particular attention as improper handling can damage the umbilical or create hazardous situations. Launch and recovery crews must coordinate precisely during vehicle handling to prevent equipment damage or personnel injury. Many organizations maintain certification programs that verify competency before personnel participate in operational deployments. Ongoing proficiency requirements ensure skills remain current despite potentially long intervals between actual ROV operations.

Maintenance Planning and Spare Equipment

Given the remote operating locations and critical nature of cable repair operations, adequate spare equipment inventory proves essential. Key spares include hydraulic hoses and fittings, electrical connectors and penetrators, thruster components, camera and lighting systems, sensor packages, and specialized tools for burial or cutting operations. The spare parts package must balance completeness against storage constraints aboard the cable ship and total mobilization cost.

Preventive maintenance between dives identifies wear and degradation before failure occurs. Inspection protocols examine seals for water intrusion, test thruster operation and electrical continuity, verify hydraulic pressure and flow characteristics, check camera and lighting function, and calibrate sensors and navigation systems. Post-dive maintenance windows provide opportunity for component replacement and system testing before the next deployment. Maintenance logs track equipment history and identify recurring issues that may indicate design deficiencies or operational procedure problems.

Documentation and Quality Assurance

Comprehensive operational records support system maintenance, inform future planning, and provide evidence of work completion. ROV operations generate several categories of documentation including pre-dive system checks and configuration logs, operational video recording throughout the mission, navigation data showing ROV track and cable position, burial depth measurements and verification records, and post-dive inspection and maintenance reports. This documentation serves contractual requirements and provides reference material for warranty claims or dispute resolution.

Video documentation proves particularly valuable for quality assurance and historical reference. Time-stamped video with position overlay creates an auditable record of work performed and conditions encountered. Many operators archive operational video for the system lifetime, providing reference material for repair planning and historical analysis of cable condition evolution. Modern systems enable real-time video streaming to shore-based engineering teams for remote technical support during complex operations.

Integration with Cable Ship Systems

ROV operations must integrate seamlessly with broader cable ship activities. Station-keeping requirements during ROV deployment influence vessel Dynamic Positioning (DP) system operation. The umbilical path between ship and ROV requires careful management to avoid interference with cable handling equipment, grapnel operations, or other vessel activities. Dedicated ROV control rooms aboard the ship provide isolated work environments for operators while maintaining communication with bridge crew and project management.

Power supply architecture aboard cable ships must accommodate ROV requirements without compromising other systems. Large ROVs may consume megawatts of power, straining vessel generation capacity during peak operations. Power management systems prioritize loads and shed non-essential consumption during peak ROV demand. Some vessels install dedicated generators or power conditioning equipment specifically for ROV operations, isolating ROV loads from navigation and communication systems that require uninterrupted power.

Limitations and Boundary Conditions

ROV technology operates within defined performance envelopes that constrain application scope. Recognizing these boundaries prevents unrealistic expectations and enables appropriate technology selection for specific operational requirements. The limitations derive from fundamental physical constraints, economic considerations, and current technological maturity rather than temporary engineering challenges.

Depth capability remains constrained by pressure vessel design and power delivery limitations. While some ROVs operate to 3,000 meters, the majority of cable work ROVs limit to 2,000-2,500 meters. Deeper operations require exponentially increasing structural strength, more robust electrical penetrations, and power transmission solutions that overcome umbilical resistance over extended lengths. Cable systems installed at depths beyond ROV capability rely on grapnel recovery for repair operations, accepting longer repair times and higher risk of cable damage during recovery.

Burial capability in very hard seabeds approaches fundamental limits. While mechanical cutting tools can penetrate rock and coral, the energy required increases dramatically with material hardness. Power delivery constraints and cutting tool wear rates make burial in hard rock impractical for extended distances. Cable routes crossing hard seabed sections may require alternative protection methods including rock dumping, concrete mattressing, or route selection avoiding the hardest materials where possible.

Weather window requirements restrict operations during severe environmental conditions. While ROVs can work underwater during storms, launch and recovery operations require acceptable sea states. Projects in regions with limited weather windows must plan for extended vessel standby time and schedule contingency. The economic impact of weather delays can exceed direct operational costs, particularly for time-sensitive repair operations affecting revenue-generating cable systems.

Future Directions

ROV technology continues evolving with improvements in autonomy, power efficiency, sensor integration, and tool sophistication. Development efforts focus on several key areas that will expand capability while reducing operational costs. However, fundamental constraints including power delivery, pressure vessel design, and human operator requirements will continue shaping ROV capabilities for the foreseeable future.

Extended depth ratings beyond 3,000 meters enable access to cables in the deepest ocean basins. This requires advances in pressure vessel materials, electrical penetrator design, and umbilical power transmission efficiency. Some development programs explore fiber optic power delivery using remote laser power transmission, though practical implementation faces significant challenges. More likely near-term improvements involve incremental depth extensions to 3,500-4,000 meters through evolutionary design refinement.

Improved autonomy reduces operator workload and enables more consistent performance. Modern ROVs incorporate semi-autonomous functions including automatic depth and heading hold, cable following using sensor fusion, and burial depth control. Future systems may execute complete burial missions under supervisory control rather than continuous manual piloting. However, repair and manipulation tasks will likely require human operators for the foreseeable future due to their unpredictable nature and requirement for judgment-based decision making.

Enhanced manipulation capabilities for complex tasks including connector mating, tool changeout, and multi-step assembly sequences expand ROV application scope. Advanced manipulators with improved force feedback, greater degrees of freedom, and automated tool handling enable operations currently requiring diver intervention or surface recovery. This capability particularly benefits scientific cable systems and offshore platform connections where complex interventions are required at installed equipment.

Better power efficiency extends mission duration and reduces vessel generation requirements. Improvements in thruster design, hydraulic system efficiency, and power electronics reduce energy consumption for equivalent work output. More efficient systems enable longer dives between recovery cycles or operation from smaller vessels with limited power generation capacity, expanding the pool of vessels capable of supporting ROV operations.

Engineering Principles for ROV Operations

- Vehicle selection must align with water depth, seabed conditions, and operational requirements rather than selecting the largest or most capable system available

- Environmental operating limits including current, visibility, and sea state should drive realistic mission planning and schedule development with appropriate contingency margins

- Umbilical management represents a critical single point of failure requiring constant attention and proper maintenance protocols throughout operations

- Operator skill and experience directly influence mission success more than vehicle capability differences within appropriate equipment classes

- Launch and recovery operations present the highest risk phases of ROV deployment and merit special attention to weather windows and equipment condition

- Post-lay burial requires careful slack management during initial cable laying to enable effective ROV trenching without excessive cable tension that could damage optical fibers

- Integration between ROV operations and cable ship activities demands clear communication protocols and coordination procedures verified through pre-deployment planning

- Comprehensive spare parts inventory and preventive maintenance programs reduce downtime and enable sustained operations in remote locations where resupply is impractical

- Documentation including video records and navigation data provides essential quality assurance evidence and supports future maintenance planning and warranty administration

- Hybrid operational approaches combining ploughs for bulk burial with ROVs for specialized sections optimize overall project efficiency while maintaining protection completeness

Conclusion

Remotely Operated Vehicles have established themselves as essential technology throughout the submarine cable system lifecycle. From pre-installation surveys through decades of operational maintenance, ROVs enable interventions that would otherwise be impossible or economically impractical. The technology continues evolving with improvements in power delivery, sensor integration, autonomy features, and tool sophistication, though fundamental constraints including umbilical power transmission and pressure vessel design will continue shaping capabilities.

Successful ROV operations depend on matching vehicle capabilities to mission requirements, maintaining operational discipline during deployment and recovery, investing in crew training and experience development, planning for environmental limitations and weather windows, integrating ROV activities with broader cable ship operations, and maintaining robust equipment maintenance and spare parts programs. Organizations that invest in their ROV programs through equipment acquisition, personnel development, and operational experience accumulation position themselves for success in an industry where underwater intervention capability increasingly differentiates operational excellence.

The fundamental principles of ROV operations remain constant despite technological evolution. Skilled personnel operating well-maintained equipment according to proven procedures achieve reliable results across diverse operating conditions. As submarine cable systems extend into deeper waters and more challenging environments, ROV capability requirements continue increasing. Development efforts focus on extended depth ratings beyond 3,000 meters, improved autonomy to reduce operator workload, enhanced manipulation capabilities for complex tasks, better power efficiency to extend mission duration, and integration with emerging autonomous systems. These advances will enable more ambitious cable routes while maintaining the reliability and cost-effectiveness that the industry requires.

SEO Keywords: ROV operations, submarine cable installation, remotely operated vehicle, cable burial systems, PLIB operations, LARS deployment, TSS cable detection, umbilical management, thruster propulsion, cable depressor, post-lay burial, marine cable repair, jetting systems, SCARAB ROV, underwater robotics

References

- ITU-T Recommendation G.971 (2024), General features, design and testing of optical fibre submarine cable systems. International Telecommunication Union.

- ITU-T Recommendation G.972 (2024), Definition of terms relevant to optical fibre submarine cable systems. International Telecommunication Union.

- Wood, M., et al. (2016), Undersea Fiber Communication Systems, Chapter 17: Marine and Maintenance. Academic Press.

- Chesnoy, J., et al. (2016), Undersea Fiber Communication Systems, Chapter 8: New Applications for Submarine Cables. Academic Press.

- ITU-T G-series Recommendations - Supplement 41 (2024), Design guidelines for optical fibre submarine cable systems. International Telecommunication Union.

- SubOptic Conference Proceedings (Various), Technical papers on submarine cable installation, maintenance, and ROV operations. SubOptic Foundation.

- Sanjay Yadav, Optical Network Communications: An Engineer's Perspective – Bridge the Gap Between Theory and Practice in Optical Networking.

Unlock Premium Content

Join over 400K+ optical network professionals worldwide. Access premium courses, advanced engineering tools, and exclusive industry insights.

Already have an account? Log in here