Understanding Optical Return Loss

Optical fiber communication professionals might have heard about ORL (Optical Return Loss ) during design and operation on an Optical Fiber Network. Intend of this article is to share the information on this topic which could help optical fiber engineers and professionals understanding the concept and they can utilize this knowledge to understand a network in a better way.

In this article we will discuss

-What is ORL?

-What are the major sources of ORL ?

-What are the implications of ORL?

-How to test and rectify ORL?

-Methods to help improve ORL.

-Standards and references

What is Optical Return Loss (ORL)?

Let me share few definitions so that it will be easy for every stage of engineers ;it could be student, beginner, professional or expert.

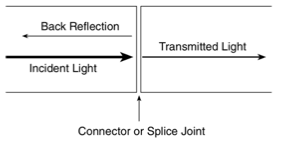

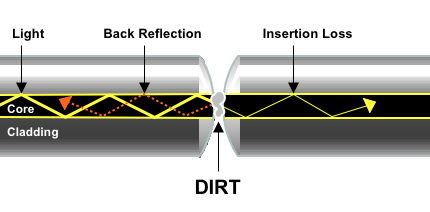

1). When light passes through an optical component most of it travels in the intended direction, but some light is reflected or scattered. In many applications these reflections are unwanted, because they can affect the emission characteristics of any laser in the system. In such applications, it is important to measure the reflections for the components of the system. The Return Loss is defined as the light reflected back into the input path. It is caused by scattering and reflection from optical surfaces like mirrors, lenses, and connectors or from defects, such as cracks and scratches. The back-reflection is equal to the return loss with a negative quantity.

2). ORL is defined as the ratio (in dB) of the optical power (Pinc) traveling downstream at a system interface to the optical power reflected back upstream to the same interface.

This includes the reflected power contributions from all system components downstream from the interface.

To clarify :

Reflectance (dB) = P reflected (dBm) – P incident(dBm)

A discrete reflection will always be a negative quantity as the reflected power cannot be greater than the incident power.

By convention ORL is defined as:

ORL(dB) = P incident (dBm) – P reflected (dBm)

This means that ORL will always be a positive number.The fact that we want all power to move forward and none to be reflected means that the higher the positive number, the better.

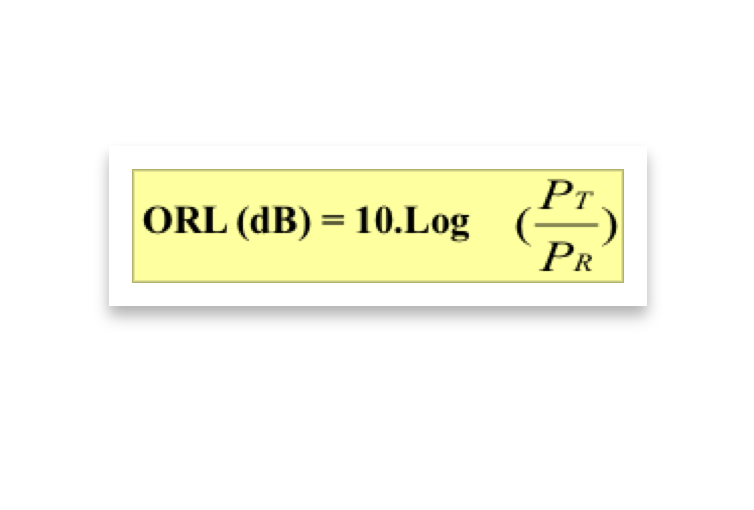

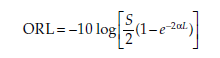

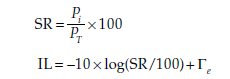

3). The reflection factor for a component is a measure of how much light the component reflects. It is a ratio of the power reflected by the device to the power incident on the device. More normally we talk about the return loss of a component. The return loss has units of dB. Return loss is given by:

![]()

Return Loss(dB) = –10log(Reflection Factor) (dB)

ORL(dB) = P incident (dBm) – P reflected (dBm)

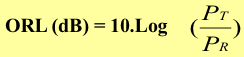

4). Optical return loss is the ratio of the output power of the light source to the total amount of back-reflected power

(reflections and scattering). It is defined as a positive quantity.

PT: Output power of the light source

PAPC: Back-reflected power of APC connector

PPC: Back-reflected power of PC connector

PBS: Backscattered power of fiber

PR: Total amount of back-reflected power

ORL is measured in dB and is a positive value.Reflectance (dB) is the ratio of reflected power to incident power due to a single interface. It is defined as a negative quantity

ORL is measured in dB and is a positive value.Reflectance (dB) is the ratio of reflected power to incident power due to a single interface. It is defined as a negative quantity

The higher the number, the smaller the reflection – yielding the desired result.

What are the major sources of ORL ?

System components such as

- connectors,

- mechanical splices,

- attenuators,

- patch cords

- glass/air terminations

All create a change in index of refraction as seen by an optical signal. The components are reflective in nature and can contribute to system ORL.

The fiber optic cable itself creates backscatter as light propagates through it. The amount of reflected power due to backscatter cannot be eliminated but is magnitudes smaller than the power from discrete reflections

Sources of loss include reflections and scattering along the fiber network. A typical Return Loss value for an Angled Physical Contact (APC) connector is about -55dB, while the RL from an open flat polish to air is typically about -14dB. High RL is a large concern in high bitrate digital or analog single mode systems and is also an indication of a potential failure point, or compromise, in any optical network.

What are the implications of ORL?

The main effects of back-reflection due to ORL include the following:

- Less light is transmitted from the transmitter.

- Increase in light source interference

- Increasing the BER in digital transmission systems

- Multi path distortion can also occur.

- Reducing the OSNR in transmission

- Reflections can distort the optical signal as reflections travel back and forth between reflective components.

- Strong fluctuations in the laser output power.

- Increase in transmitter noise.

- Changes central wavelength and output power.

- Permanent damage to the laser.

How does reflected power affect laser stability ?

Reflected light can provide unwanted feedback to the laser cavity which will effect:

- Frequency Modulation Response changes

- Relative Intensity Noise (RIN)

- Optical frequency variations

- Laser line-width variations

Reflection induced degradation increases with system bit-rate !The end result is higher bit error rates (BER)

How to test ORL?

The measurement of ORL is becoming more important in the characterization of optical networks as the use of wavelength-division multiplexing increases. These systems use lasers that have a lower tolerance for ORL, and introduce elements into the network that are located in close proximity to the laser

The two major test methods:

Optical Continuous Wave Reflectometry (OCWR)

A laser source and a power meter, using the same test port, are connected to the fiber under test.

Optical Time Domain Reflectometry (OTDR)

The OTDR is able to measure not only the total ORL of the link but also section ORL.

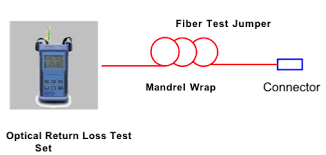

To measure the ORL of a fiber span, an optical continuous wave reflectometer (OCWR) is used. The OCWR is an instrument designed to specifically measure system and component ORL reflectance. The OCWR launches a stable, continuous wave signal into the optical fiber and measures the strength of the time-integrated return signal. The ORL meter will return a single negative value which is the total reflectance from all reflective components seen from the point of test. On fiber spans with multiple reflective components, discrete reflectance values cannot be determined unless component isolation is performed. The measured reflectance value is a directional value so tests should be performed on both ends of a fiber span.

The ORL reference measures background reflection of the fiber under test. The reference procedure is performed each time a new test setup is required.A mandrel wrap is applied to the fiber test jumper before the point of measurement to isolate and attenuate any reflectance generators. The glass to air interface on the test connector end will be isolated from the OCWR. The ORL zero function on the OCWR provides storage of the background reflectance level to provide the total optical return loss of the fiber test jumper. Once the mandrel wrap is taken out, the displayed ORL value represents the total ORL of the system from the point of termination.

Typical OTDR report snapshot for reference:-

Methods to help improve ORL are as follows:

- Use ultra polish connectors that have low reflectance such as UPC type. APC type connectors have even better reflectance values but are not compatible with other non-APC connectors. Connection to a non-APC connector can damage the APC connector.

- Use fusion splices instead of mechanical connectors or mechanical splices where possible.

- Re-do fusion splices that are shown to have reflectance. A good fusion splice should have no reflectance.

- Install optical isolators at the laser to reduce back reflectance.

Typical Reflectance for few connectors:-

PC connecters: -30dB to –40 dB

UPC connectors: -40dB to –50dB

APC connectors: -60dB

Fiber to air interface on a PC connector: -14.7 dB

Rayleigh backscatter for telecom fiber: -70 dB/meter

The angle reduces the back-reflection of the connection.

Typical good ORL measurements range from 30-35 dB.

Standards and references

-Telcordia document GR-1312

R7-79 [361] The discrete reflectance seen from any ONE optical port shall be less than -27 dB.

O7-80 [362] The discrete reflectance seen from any ONE optical port should be less than –40dB.

-Telcordia Document GR-2918

R7-38 [35] The individual channel Optical Return Loss, ORL as defined above, shall be 24dB or more for all wavelengths used in the DWDM system.

All equipment and component manufactures are required to design their systems to meet reflectance specifications set out by the ITU-T which are adopted by bodies such as Telcordia (formerly Bellcore).Their specifications are intended to minimize system degradation due to reflections and they propose:

1)Enforce reflectance requirements on individual components in a fiber span.

R7-79 and O7-80 relate to system components.

Taken from GR-1312, Issue 3, April 1999

Generic Requirements for OFAs and Proprietary DWDM systems.

2)Ensure system performance to have a tolerance to specified reflection values.

R7-38[35] relates to system ORL.

Taken from GR-2918-CORE, Issue 4, December 1999

Note :This article is sourced from multiple informations available on internet and books.

Unlock Premium Content

Join over 400K+ optical network professionals worldwide. Access premium courses, advanced engineering tools, and exclusive industry insights.

Already have an account? Log in here